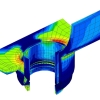

The main direction of the company Mubatec GmbH is the introduction of a new methodology for estimating the residual life of complex technical facilities. The calculation-experimental approach to the analysis of actual operational losses in time uses data on the actual thermosensitive load of the controlled object of deformation, displacement, temperature, vibration and acceleration, obtained from a universal online monitoring system. The data obtained in the first stage for evaluating the results of computational modelling of the stress-strain state of the object and at the second stage, for creating a history of operation of the facility for the past and future period of time.

The proposed approach is patented and is successfully used to justify the safe operation of critical areas of equipment for pipelines of buildings and structures of nuclear power plants (NPPs). The methodology "RESOURCE-EXPERT MUBATEC Universal Methodology for Ageing Management of Systems Structures and Components of Technical Objects". Allows:

- To estimate with a high degree of reliability the residual resource of various technical objects;

- Causes of the consequent connection of non-projected damage and destruction of structures;

- Give recommendations for modernization in order to reduce operational damage;

- Identify weaknesses in the design, in order to optimize the operational control and maintenance of the facility.

The hardware of the monitoring system is built on a unified modular design using 3 variants of National Instruments platforms (PXI, CompactRIO and WSN) depending on the task. The software for numerical calculations of the stress-strain state and the accumulated operational stress and damageability is the development of the firm Mubatec GmbH that allows the calculation of the justifications for the purpose of peer review in real time. The monitoring system also includes a module for non-destructive expert control of actual defects, built on a combination of remote ultrasonic and acoustic monitoring systems. The monitoring system operates in a remote stand-alone mode for up to 1 year without additional maintenance.

Mubatec GmbH will develop and supply these systems for a wide range of production tasks.

Mubatec GmbH has a modern laboratory base for conducting complex materials research.

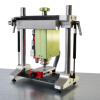

For many years, employees of Mubatec GmbH are engaged in the development of methods for non-destructive, unrestricted control of the mechanical properties of materials based on the method of instrumental indentation. Specialists of Mubatec GmbH issued GOST R 5232-2014. For the practical implementation of new approaches to non-destructive testing, Mubatec GmbH has manufactured the Mubatec HU-1 instrument for monitoring in laboratory and production conditions.

In order to manage the resource characteristics, Mubatec GmbH is developing new technologies that reduce the level of operational damage of welded joints using surface strain hardening, as well as robotic means for its usage in industry.