The MUBATEC instrument base meets the modern requirements for conducting scientific research in the field of mechanical testing and materials science:

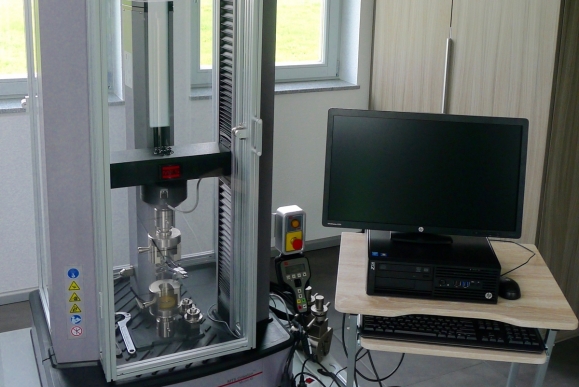

- For the standard statistical mechanical tests for tension (Tensile), compression (Compression), bending (Bend), the electromechanical universal machine MTS Criterion Series 43 (Electromechanical Universal Test System) is used.

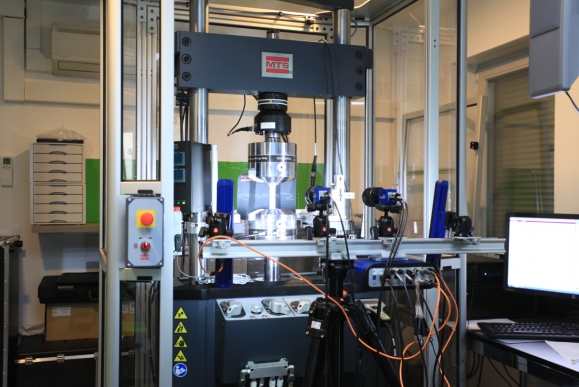

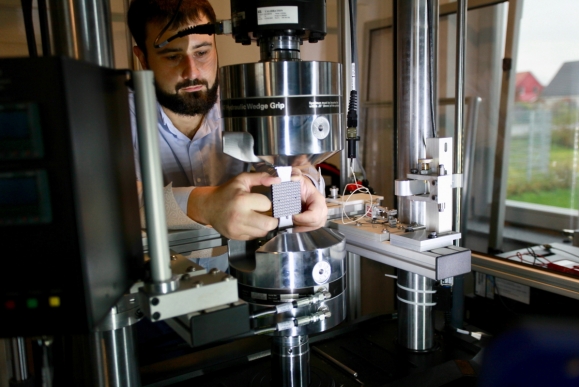

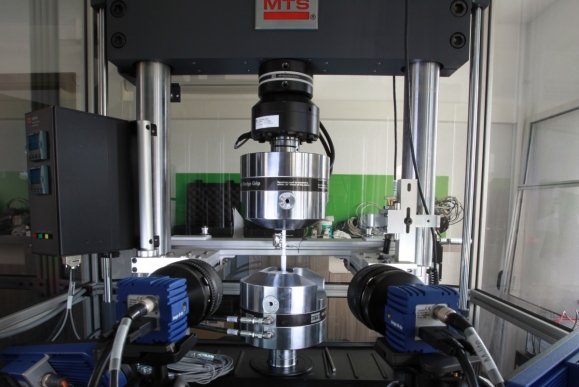

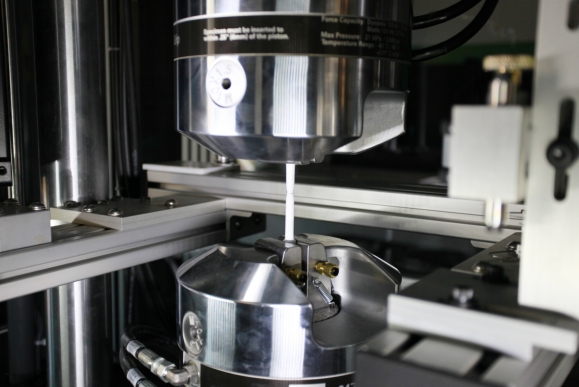

- The MTS Landmark 370 servo-hydraulic machine is used for researching materials in a wide range of static, dynamic loads and temperatures. This machine allows testing equipment for low-cyclic and high-cycle fatigue, crack resistance at temperatures up to 1200 °C, and also test individual components (Component Testing) Modeling static and dynamic operational impacts.

- For testing Brinell, Vickers, Rockwall and Knoop hardness tests, the Zwick / ZHU 250 universal hardness tester is used. For metallographic testing, the Remet range of micro test sample preparation instruments is used.

- The microstructural analysis is performed with a Leica microscope using the specialized analytical software.

- Various ultrasonic flaw detectors are used for expert ultrasonic testing, including those with phased gratings from Omniscan.

- To diagnose underground pipelines and vessels, a complex of instrumentation for search and control is used. So for dispositional examination of the actual state, the robot of iPak company is equipped with a system of visual optical, laser and ultrasonic control of surface defects.

- For the control of buildings and structures, instruments for non-destructive testing of mechanical properties and defects in concrete, as well as thermal imagers and the 3D laser scanner Leica 10 are used.

The MUBATEC instrument cluster is regularly split.