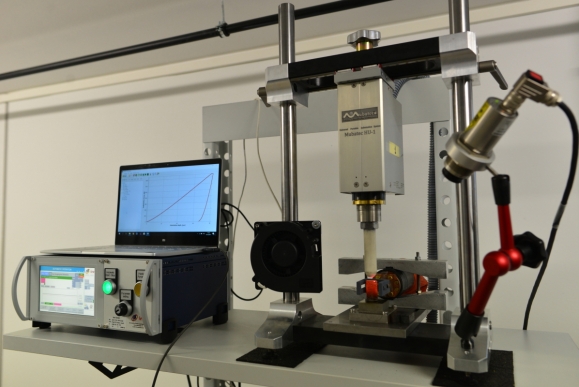

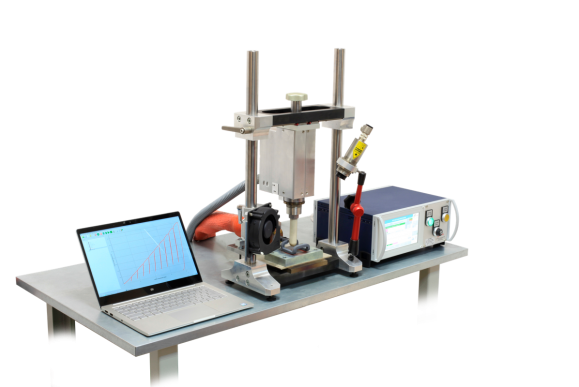

To expand the methodological and technical capabilities of the universal portable hardness tester (Universal Potential Indentation System), the MUBATEC UH-1 has developed a compact induction heating system integrated into the laboratory hardness tester. Induction heating in the used sample under the influence of an alternating electromagnetic field creates eddy currents, converted into thermal energy due to hysteresis losses. Due to this, during induction heating, heat is transferred directly to the sample. In connection with this, a high efficiency is achieved, since only indirect heating of the environment occurs. Therefore, to conduct laboratory tests of samples using instrumental indentation, an induction generator with flexible frequency control was developed, with automatic adaptation to the resonance frequency of the current. The heating depth of the controlled sample depends on the properties of the material being monitored and the frequency of the current creating an alternating electromagnetic field generating eddy currents in the sample. High frequencies first heat only the surface of the sample to a shallow depth, medium and low frequencies are suitable for heating the entire volume of the test sample. Depending on the purpose of the test, the properties of the material and the size of the sample, a selection of the heating regimes is carried out.

The MUBATEC HU unit is equipped with a test system for samples made of all electrically conductive materials and a number of non-conductive materials by instrumental indentation, as well as performing complex testing of sample materials with induction hardening, induction tempering and annealing modelling during testing. The MUBATEC HU induction heating system has a high-frequency generator of 5 kW, a computer control unit for heating modes with wide control capabilities, heating duration, current control and temperature. A large library of heating modes is stored in the memory of the device, depending on the characteristics of the test samples.

Control over the heating mode is carried out automatically according to the test parameter in accordance with the selected test modes (the modes are selected from a clear interface with the help of the touch screen of the display.) Cooling of the inductor is carried out with the help of an autonomous cooler.

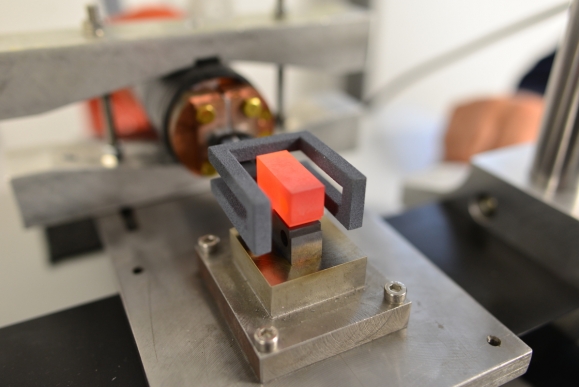

The installation is completed with several variants of inductors depending on the shape of the controlled samples.

The choice of the test area is carried out by the operator using a specialized optical system consisting of a video camera and an automated carriage that moves the measuring device of the hardness meter with respect to the controlled sample.

The indentor unit has a specialized design and is made of high-strength ceramics taking into account high-temperature tests. The induction heating device allows testing in a wide range of operating temperatures from 150 to 1000 °С .